Services

we have a team of trained and certified professional engineers with hands on industrial experience

we also deal with most of the process control systems platforms more

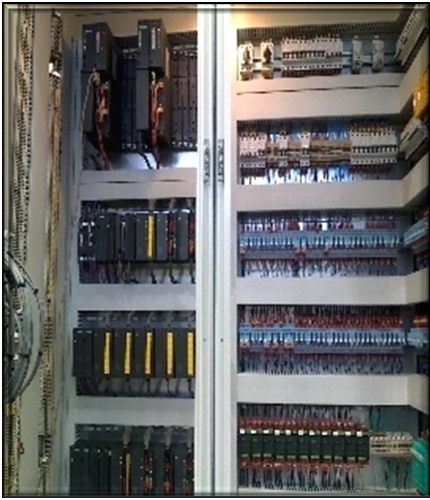

ICSS design, engineering and validation

Our team is expert in delivering the solutions right from the feasibility to the deployment stage adhering to the applicable standards and regulations. Whether the task is EC&I documentation generation, PLC, DCS programming/configuration, or system validation requirements, we are experienced and certified to provide our services.

Factory & site acceptance testing and verification

We can assist in expediting the closure of open/punch list items during testing and commissioning stages for various process & rotating equipment control, safety and mitigation-based control systems.

Site support and troubleshooting

We are readily available on short notice both offshore and onshore locally & internationally to provide the site troubleshooting with detailed report generation highlighting the causes and recommendations to avoid the future event occurrence.

Functional safety assessment

All FSA stages of SIS safety life-cycle are taken care of either as a completely independent or part of a team. We can also participate in HAZOP & SIL studies as an EC&I representative and can generate the detailed SRS.

Alarm management

Where the facility is new or existing, we provide the alarm rationalization and optimization studies to reduce the number of nuisance alarms as per the required KPIs. Alarm philosophy document can also be reviewed, created and modified as per the customer requirements.

Instrumentation solutions

Whether the process measurements are inaccurate, analyzers are not matching with the process dynamics or control loops are unstable, we will be happy to assist with tuning, calibration and installation checks, also we able to provide complete design and upgrade solution for the faulty or obsolete installed instrumentation.

Procurement support

We supply an electrical and instrumentation spares at competitive price along with technical support and reduced lead time. we also provide inspection witness services for critical long lead items on behalf of our clients.

Trainings and courses

Customized and hands-on training of various control system offered with programming, maintenance and diagnostics categories.